Maximizing Accuracy: Guide to Using Profile Projectors

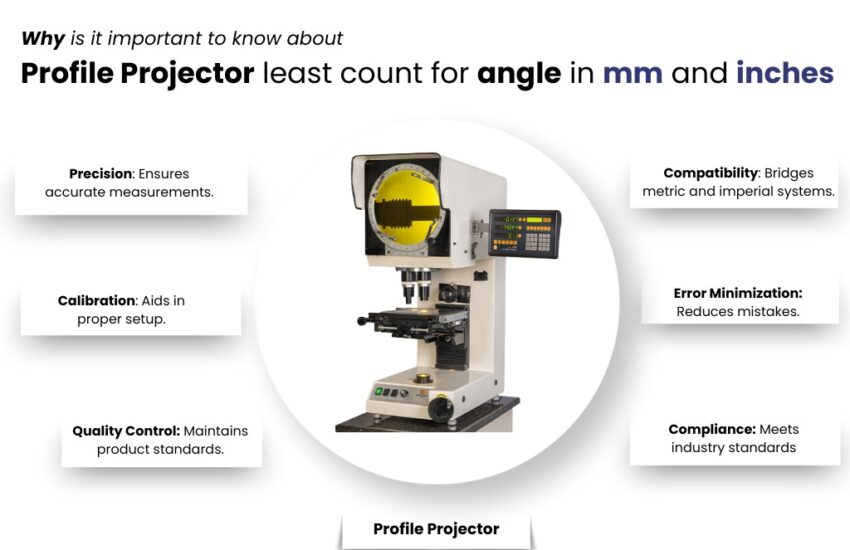

Profile Projector Measurement Machines, also called Optical Comparators, are vital tools for precise measurement and inspection in different industries. They help assess dimensions and intricate details of workpieces accurately, ensuring reliability in the manufacturing process.

What is a Profile Projector Measurement Machine?

A Profile Projector is like a super magnifying glass that shows a big picture of something tiny on a wall. It helps people look really closely at the shape and size of an object and measure it accurately. This gadget uses special tricks with light to make the object look much bigger and easier to study.

How Does a Profile Projector Work?

A Profile Projector works like a super-powered magnifying glass. It uses a bright light to shine on an object placed on a platform. With special lenses and mirrors, it makes a big, zoomed-in picture of the object on a screen. This big picture helps experts carefully check and measure things like how far apart points are, the angles, curves, and other important details of the object they’re looking at.

Benefits of Utilizing Profile Projector Measurement Machines

- Accuracy and Precision

Profile projectors are really good at making sure things are just right. They help measure stuff accurately, making sure that things we make are exactly how they’re supposed to be. This is super important in industries like airplanes, cars, and electronics because even small mistakes can cause big problems.

- Efficiency in Inspection

A Profile Projector quickly and accurately checks lots of different sizes and tiny details. This helps speed up how fast we can inspect things. Because it’s faster, it means we can get more done and our machines don’t have to stop as much for checking things, which is really helpful for making more stuff without delays.

- Enhanced Quality Control

These machines help make sure things are just right. They help companies find mistakes or differences in the stuff they make quickly, so they can fix them and keep making really good quality stuff.

- Versatility and Adaptability

Profile Projectors can handle all sorts of parts, no matter how big, small, simple, or complicated they are. They’re really useful in different industries because they can check and study lots of different things.

Procedure for Utilizing a Profile Projector Measurement Machine

- Stage Adjustment

- Use the stage controls to position the sample under the lens. Adjust the X-Y axis and focus knobs for precise alignment.

- Illumination Selection

- Select the appropriate illumination method (profile, surface, or contour) based on the specific features you intend to measure.

- Magnification Selection

- Choose the magnification level suitable for the measurements. Ensure it provides sufficient detail without compromising accuracy.

- Image Projection

- Activate the projection to display the image of the part on the screen. Rotate or tilt the part if needed to view different angles.

- Measurement Tools

- Utilize the measuring tools such as crosshairs, grids, and edge detection to accurately assess dimensions and features.

- Data Collection

- Take measurements by utilizing the digital readout or by manually recording readings. Ensure consistent and accurate data collection.

Troubleshooting

- Inaccurate Measurements: Check for misalignment, calibration issues, or dirt obstructing the lens.

- Flickering Image: Verify the stability of the electrical connections and the bulb.

Conclusion

Profile Projector Measurement Machines, along with dimensions measuring instruments, are super important for making sure things are just right in manufacturing. They’re like the superheroes of checking if things are precise and top-notch quality. They help make sure everything’s accurate and speed up how things get done in lots of different industries. They’re a big deal because they help make sure stuff is made really well and exactly how it should be.

If you have any questions or need more information, feel free to reach out to our technical expert. You can contact us at info@sipconinstrument.com or call us at +91 82229 29966.