Why Measuring Microscopes Are Essential Tools in Quality Control Processes

In today’s competitive world, the crucial part of any manufacturing process is to maintain high-quality standards. Even if the production is of some tiny electronic components or complex mechanical parts, the need for precision is everywhere. This is where measuring microscopes come into action and play a vital role in quality control processes.

What Are Measuring Microscopes?

Measuring microscopes are advanced optical instruments that are not just used for viewing small objects, they also measure them precisely. Not like regular microscopes, these are equipped with advancements like scales, digital displays, and software that help operator’s measure dimensions like length, width, angles, and more with amazing accuracy.

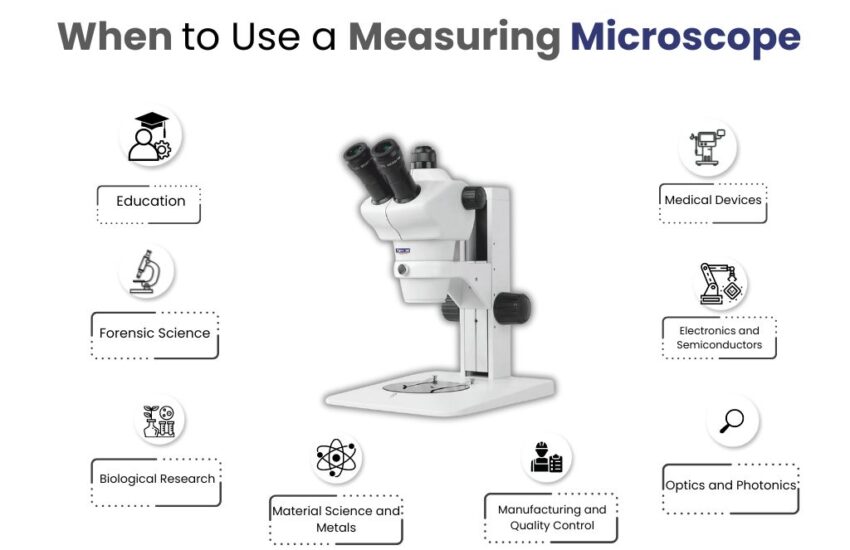

These microscopes are generally used in industries like electronics, automotive, aerospace, manufacturing, etc. These are the industries where a minimal error can’t be afforded. Let’s just explore why it is very important in quality control. Let’s ride the knowledge train.

Ensuring Precision and Accuracy

The first and foremost role of a measuring microscope is to ensure that all the components meet their required specifications. In manufacturing, a tiny difference can lead to a product malfunction, which can cause a very disgraceful result. For instance, in the automotive industry, the smallest error in any component can lead to an entire vehicle failure which can lead to deadly consequences.

Measuring microscopes work for various measuring tools and ensure that every single component is within the tolerance limits. This precision and accuracy help to maintain consistency in production and ensures that the risk of supply of defective products will be minimized.

Detecting Defects Early

One of the crucial functions of measuring microscopes is their ability to identify defects that are not possible to even see with the naked eye. The defects include small cracks, and surface irregularities that will affect the performance of the whole product.

The early identification of defects in the production process helps in taking corrective actions beforehand. It not only saves time, cost, and resources but also helps in maintaining the quality of the product.

Improving Efficiency and Reducing Waste

It plays a significant role in improving the efficiency of the production process. It ensures that the component is within the specified tolerances, microscopes help in minimizing the likelihood of rework, scrap, and waste.

A very basic rule in every industry is “Time is Money”. With the help of measuring microscope, the errors can be detected earlier and help in maintaining the smooth production process.

Supporting Compliance with Industry Standards

In various industries, working as per the strict quality standards is not just a formality but it’s mandatory. The regulatory bodies often set specific standards for the products to ensure safety, reliability, and high quality. The perfect example of the same is the medical device industry, where components should meet specific regulatory requirements before they come into use as safe medical equipment.

Measuring microscopes helps manufacturers to comply with the defined standards by giving accurate measurement results and detailed reports. These reports can play a very important role at the time of audits and ensure that the product is safe for customer use.

Enhancing Research and Development

Measuring microscopes plays a very important role in research and development (R&D). The research teams use these microscopes to analyze prototypes, develop an understanding of new products, and test various designs.

These details are very important for developing new and innovative products which meet the highest quality standards. Measuring microscopes helps in developing cutting-edge products that are reliable and efficient.

Conclusion

The measuring microscopes are a very crucial tool in the quality control processes of various industries. The ability of measuring microscopes to provide precise measurements, detect defects, improve efficiency, and support R&D that makes essential for maintaining high-quality standards in various industries.

Industries are evolving the demand for precision is increasing, and the importance of measuring microscopes increasing day by day. Investing in advanced tools helps in producing better products and that’s not it, better products also enhance the company’s reputation.

If you want to get more information measuring microscope you can reach out to us on our website and find the perfect one for your application.