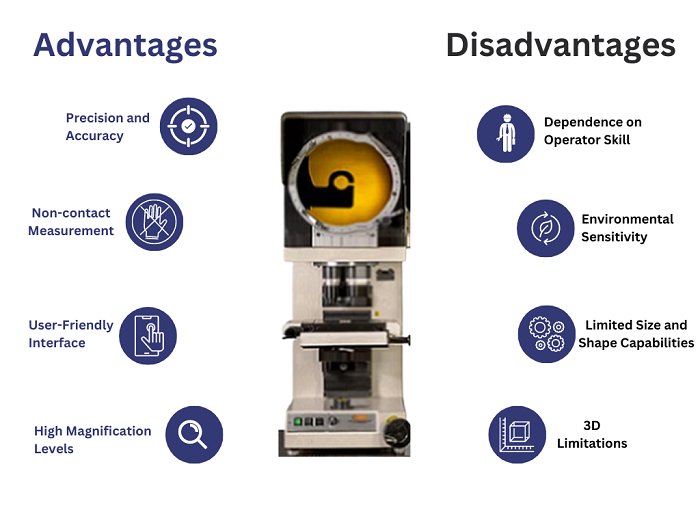

Advantages and Disadvantages of the Profile Projector

The profile projector is a tool used in manufacturing and reverse engineering to measure the dimensions of an object with high accuracy. Despite its widespread use, the profile projector comes with its own set of advantages and disadvantages. This article helps you make an informed decision.

What is a profile projector?

A profile projector is an optical tool that shows a magnified profile of a component onto a screen for measurement. This is the most used in the inspection of manufactured components.

Advantages of Profile Projector

Precision and Accuracy

Profile projectors can provide precise and accurate measurements. Magnification allows the detailed inspection of a small part, ensuring high-quality production standards.

Non-contact Measurement

Profile projectors offer a plus point of non-contact measurement, which is important for delicate or soft materials which can be damaged by the contact measurement.

High Magnification Levels

Offering magnification levels ranging from 10x to 100x helps measure small parts that can’t be examined by the naked eye.

Versatility in Applications

Profile projectors can adapt to different applications. This tool is versatile and can be used in various fields, including plastic manufacturing, metalworking, and electronics.

User-Friendly Interface

Profile projectors do not require much technical knowledge to operate. It is designed with user-friendly interfaces so that operators can measure the component without facing complexity. This ease of use enhances efficiency and productivity in measurement tasks.

Disadvantages of Profile Projector

Limited Size and Shape Capabilities

A notable disadvantage is their limitation in handling objects of certain sizes and shapes. Large or bulky items may not fit within the device’s measuring area, restricting its use to smaller components.

Dependence on Operator Skill

While user-friendly, the level of accuracy of measurement is majorly dependent on the operator’s skill and experience. If the operator is not correctly handling the component, then it may lead to measurement errors.

Environmental Sensitivity

Profile projectors require a controlled environment for optimal operation. sensitive environmental conditions may affect measurement accuracy.

3D Limitations

Profile projectors are primarily used for 2D measurement capabilities. 3D measurements are not possible by profile projectors, additional tools or methods may be necessary to analyze 3D measurement.

Conclusion

Profile projectors remain indispensable tools in precision measurement instruments. Their advantages in accuracy, precision, and versatility make them invaluable in various industrial applications. By understanding these aspects industries can leverage profile projects to achieve unparalleled precision and quality on their products.

FAQs

What makes a profile projector different from other measurement tools?

A profile projector magnifies the silhouette of an object, allowing for precise non-contact measurement, unlike many traditional tools that require physical contact.

Can profile projectors measure internal features?

While primarily used for external features, some advanced models can measure internal dimensions using specialized accessories.

Are profile projectors suitable for all industries?

While versatile, they are best suited for industries where precision and non-contact measurement of.