Cable Slicing and Insulation Thickness Measurement

Introduction

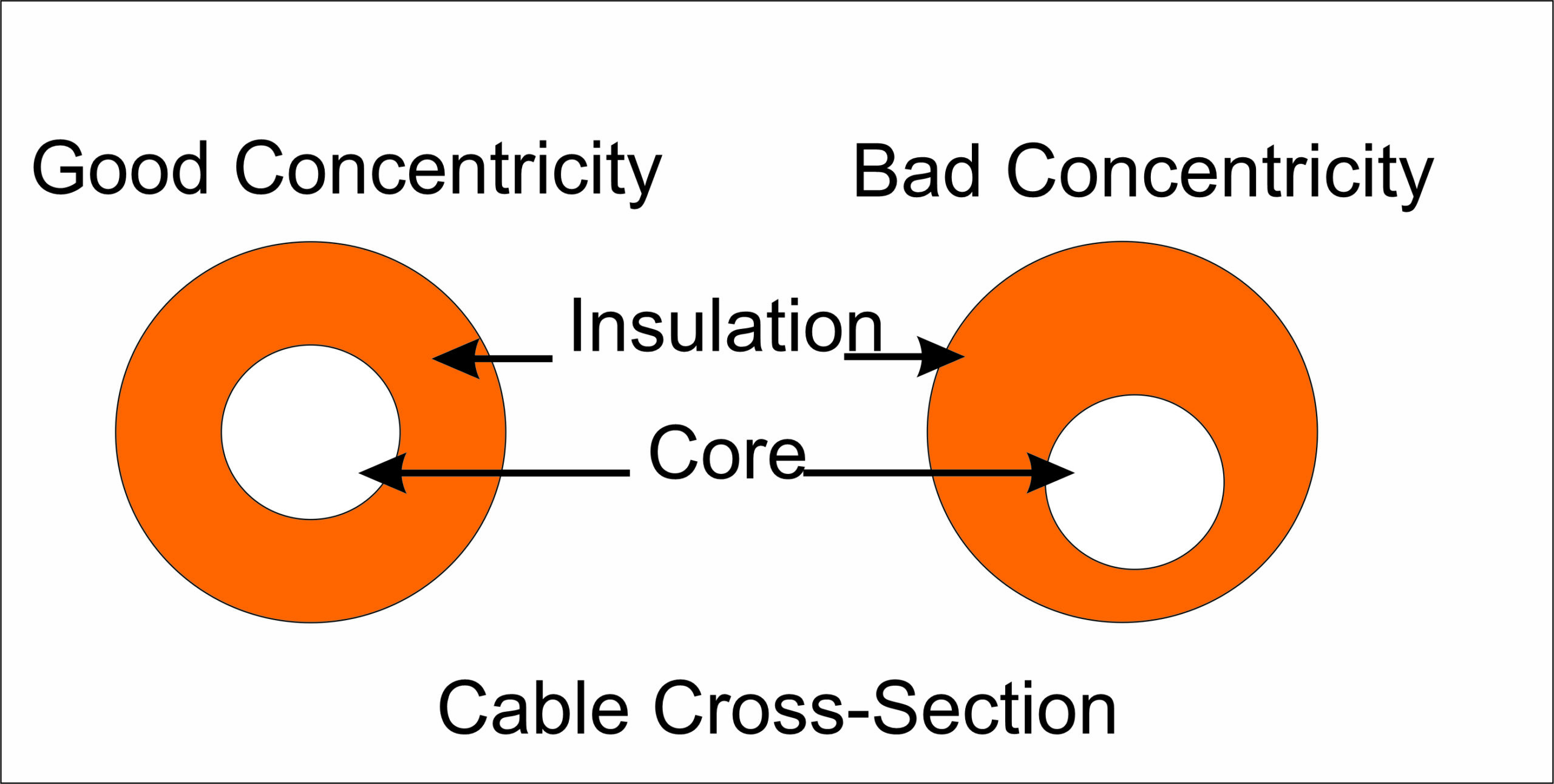

The measurement of insulation thickness is a crucial aspect of quality control in the cable manufacturing process. Accurate measurements ensure the cables meet industry standards and specifications and provide valuable information for research and development purposes. It is important to cut cable slices properly before conducting the measurement to obtain precise measurements.

Why Proper Cutting Matters

Manual cutting with blades often leads to the uneven thickness and non-parallel surfaces, which can result in incorrect measurements. This is because the blades can introduce variations in the cut, such as uneven pressure, inconsistent angles, and wavy edges. These variations can affect the accuracy of the insulation thickness measurement. In turn, this can result in incorrect product specifications, reduce the reliability of the cable, and compromise overall quality.

Benefits of Slicing Machines

To overcome these challenges, it is recommended to use a slicing machine for cutting cable slices. Slicing machines offer several advantages over manual cutting with blades. Firstly, they provide uniform and parallel sections, ensuring accurate and consistent measurements. Secondly, they can produce uniform slices with consistent thickness, reducing the variability in measurement results. Thirdly, they can be programmed to produce slices with specific dimensions, making the measurement process more efficient and consistent.

Conclusion

In conclusion, proper cable slicing is essential in the insulation thickness measurement process. While manual cutting with blades may seem convenient, it can lead to incorrect results due to variations in thickness and non-parallel surfaces. To obtain accurate and consistent measurements, it is recommended to use a slicing machine for uniform and parallel sections. This will help ensure the cables meet industry standards and specifications and provide valuable information for research and development purposes.