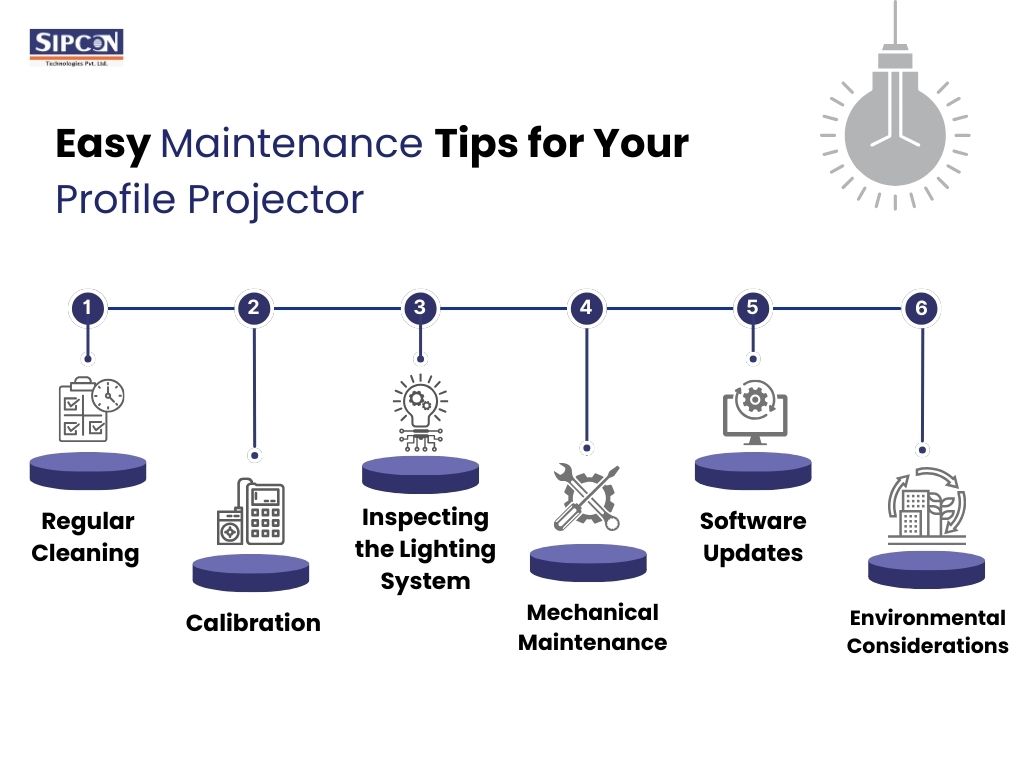

Easy Maintenance Tips for Your Profile Projector

Profile Projectors, also called optical comparators, are essential tools in the manufacturing and quality control sectors. These instruments magnify the images of the sample parts on a screen so that the measurement and inspections can be done. It’s essential to take care of your profile projector from which it will remain accurate and reliable. Here we are to help you with that, just look into the following tips to keep it intact.

Regular Cleaning

Dust and debris are the enemies of any machine because they can accumulate on the lenses and mirrors of machines and of course on your profile projector and affect its accuracy. It’s very important to clean regularly to maintain clear and precise images.

- Exterior Cleaning: Always use a soft and lint-free cloth to wipe the exterior surfaces of the projector. Don’t use any kind of harsh materials that could harm or scratch the surface.

- Lens and Mirror Cleaning: Always use a lens cleaning solution and microfiber cloth to clean the mirrors and lenses. Wipe the circular motion gently to remove the dust and smudges. Be careful that the cleaning solution does not weep into the instrument.

Calibration

How would the machine you are trusting for the measurement still work the same as when it was purchased? Regular calibration ensures that your profile projector provides accurate measurements. The Calibration should be done at least once a year or whenever you feel deviation in measurements.

- Using Calibration Standards: Calibration should be done with the help of certified calibration standards to check the accuracy of your projector. Compare the results with the standards to check the deviations if any.

- Professional Calibration Services: Prioritize for precise calibration, by considering hiring professional services. The reason behind they have the expertise and equipment to make sure that your projector is accurate and calibrated properly.

Inspecting the Lighting System

The lighting system is most important for the proper functioning of a profile projector. Inspecting the lighting components regularly is important to ensure that they are working correctly.

- Check Bulbs and LEDs: Always ensure that the bulbs or LEDs are functioning correctly and it providing consistent lighting. Look for burnt-out or flickering bulbs if there are any and replace them immediately.

- Inspect Light Guides: Clean the lights regularly to ensure optimal light transmission, and make sure that the light guides should not be cracked or obstructed.

Also read: Key Components and Their Functions in a Profile Projector

Mechanical Maintenance

The mechanical components like stage, and focusing mechanisms in a profile projector require regular maintenance to ensure its smooth operation.

- Stage Maintenance: Always keep the platform clean and dust-free. Lubricate the moving parts with light machine oil for smooth movement.

- Focusing Mechanism: Always check the focusing mechanism for any signs of wear or tear. Lubricate the moving parts and gears to maintain its smooth functioning.

Software Updates

In case your profile projector is software equipped for measurements, then keep the software up-to-date.

- Check for Updates: Check the software website on a regular basis to check for software updates if any. After updating software will be capable of bug fixing and new features that can improve the performance of the projector.

- Install Updates: Install software updates as per the instruction and from the original website only to ensure that the updates do not disrupt the ongoing measurements.

Environmental Considerations

The environment in which the profile projector is operating can impact its performance as well as its life and it can majorly be the measuring part.

- Temperature and Humidity: Maintain a stable temperature and humidity level in the room where the part is going to be measured and the projector will be used. Fluctuations and high humidity can affect the part and the accuracy and reliability of the instrument.

- Dust Control: The area around the projector should be kept as dust-free as possible. If possible use air purifiers or dust covers to minimize the dust accumulation.

Documentation and Training

Proper training and essential documentation are very important for the effective maintenance of the Profile Projector.

- Maintenance Logs: Keep a detailed log of calibrated activities, including cleaning, calibration, and repairs. This will help in keeping track of the condition of the Profile Projector to schedule future maintenance.

- Training: Make sure that all the users are trained properly and learn the use and maintenance of the Profile Projector. Proper handling is very important for the long life of the Profile Projector.

Professional Servicing

Regular Professional servicing can help you identify the issues that may be left unnoticed during routine maintenance.

- Scheduled Servicing: Schedule professional servicing at least once a year. It will ensure thorough inspections, calibration, and repairs to keep your Projector in its best condition.

- Manufacturer Support: Utilize the support of the manufacturer for servicing and repairs. They have the expertise and access to genuine parts required for the maintenance of the Profile Projector.

Conclusion

Regular maintenance is very important for profile projectors to ensure accuracy, reliability, and longevity. By following maintenance tips, can keep the profile projector in its best condition, which can provide precise measurements and inspections for manufacturing and quality control needs. A well-maintained Profile projector not only enhances the quality of the work but also saves the time and money of repairs in the long run.