Field of View Image-Based Measurement Systems

Introduction

A Field of View or FOV Image-based measurement system enables instant 2D measurement of a large number of parts and is best suited for quality control applications in manufacturing industries.

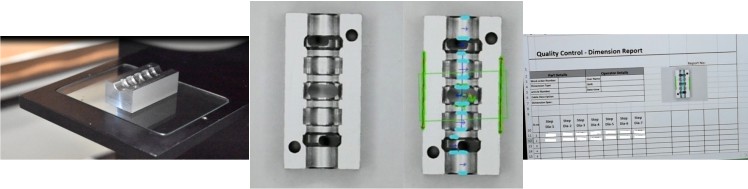

The measurement process involves placing the part on an illuminated glass platform and with a click of a mouse button or a foot switch, all required measurements (that are programmed for the part) instantly appear on the computer screen showing the dimensions that are correct (green) and those that are not (red). The system is highly cost-saving given the man-hours it saves in measuring each part through conventional methods.

Depending on the maximum part size that is to be measured, one will need a specific configuration of the system. These systems are highly accurate and generally come with a resolution/ least count of 0.1 microns and have +/- 5-micron accuracy and +/- 3-micron repeatability.

Each type of part has its own specific measurement program. Although most part profiles are included in the standard library of the system’s software. However, if a need arises a new program for a new type of part can be readily created.

Principle

A high-resolution image of the part to be measured is captured and is processed for grey information to extract edges which are further used to calculate the required dimensions.

Process

In a Field of View Image-based measurement system, a high-resolution camera acquires the image of the part to be measured. The resulting image is then used to calibrate the system. Once calibration is completed, the software can measure any dimension of the image. Also, the acquired image needs to be pre-processed to remove the random noise introduced by the ambient lighting or the system itself. A filtering algorithm removes the random noise and ensures that true contour information is fed for edge detection, which uses a sub-pixel-level (1/100th of a pixel) grey information to obtain edge points. The final measurement step uses pixel calibration value and the edge point data to calculate the dimension value in pixels.

Advantages

Field of View Image-based measurement systems work independently of the operator’s skill so that human error and operator-to-operator measurement variations are nullified. The biggest advantage of the system is the time and related costs it saves in measuring each part. With the ability to measure more than 100+ dimensions in one second, the system can quickly measure 2d dimensions in a part.