How profile projector is different from image measuring instrument

In the world of industrial measurement, there are various tools each used for unique tasks. However, profile projectors and image measuring instruments are commonly used for their unique capabilities and applications. We write this article to clarify the differences between profile projectors and image measuring instruments so that customers can make an informed decision according to their specific requirements.

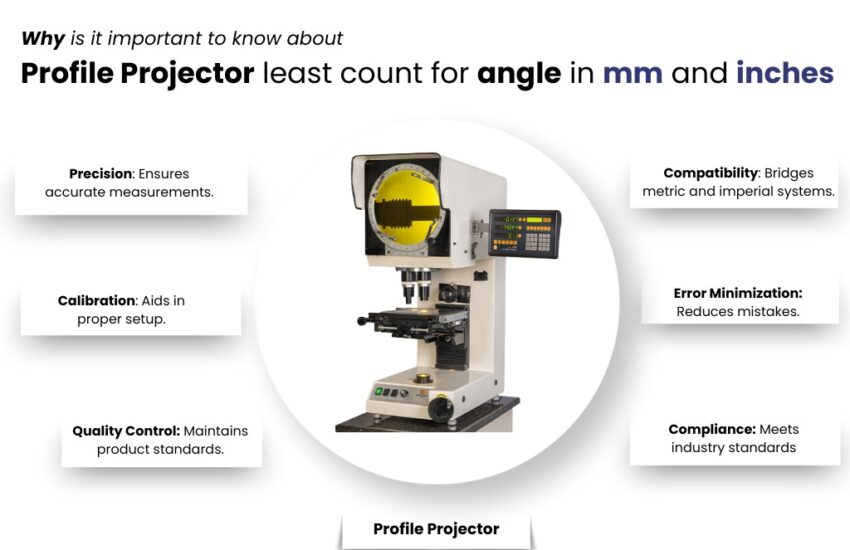

What is a Profile Projector?

A profile projector is often called an optical comparator because it is based on optical technology to measure the fine parts.

Main Features

This device uses optical technology to magnify small components for visual comparison against a standard scale.

Applications

In quality control processes where precise, repetitive measurements are crucial, particularly in manufacturing environments involving complex shapes like gears or threaded parts.

What is an Image Measuring Instrument?

An image measuring instrument is an advanced technique in comparison to a profile projector, which is based on the image capturing technique and uses software to measure dimensions and shapes.

Key Features

Equipped with a high-resolution camera and software that covers every fine geometric shape automatically.

Applications

PCB inspections and micro component analysis where precision is critical.

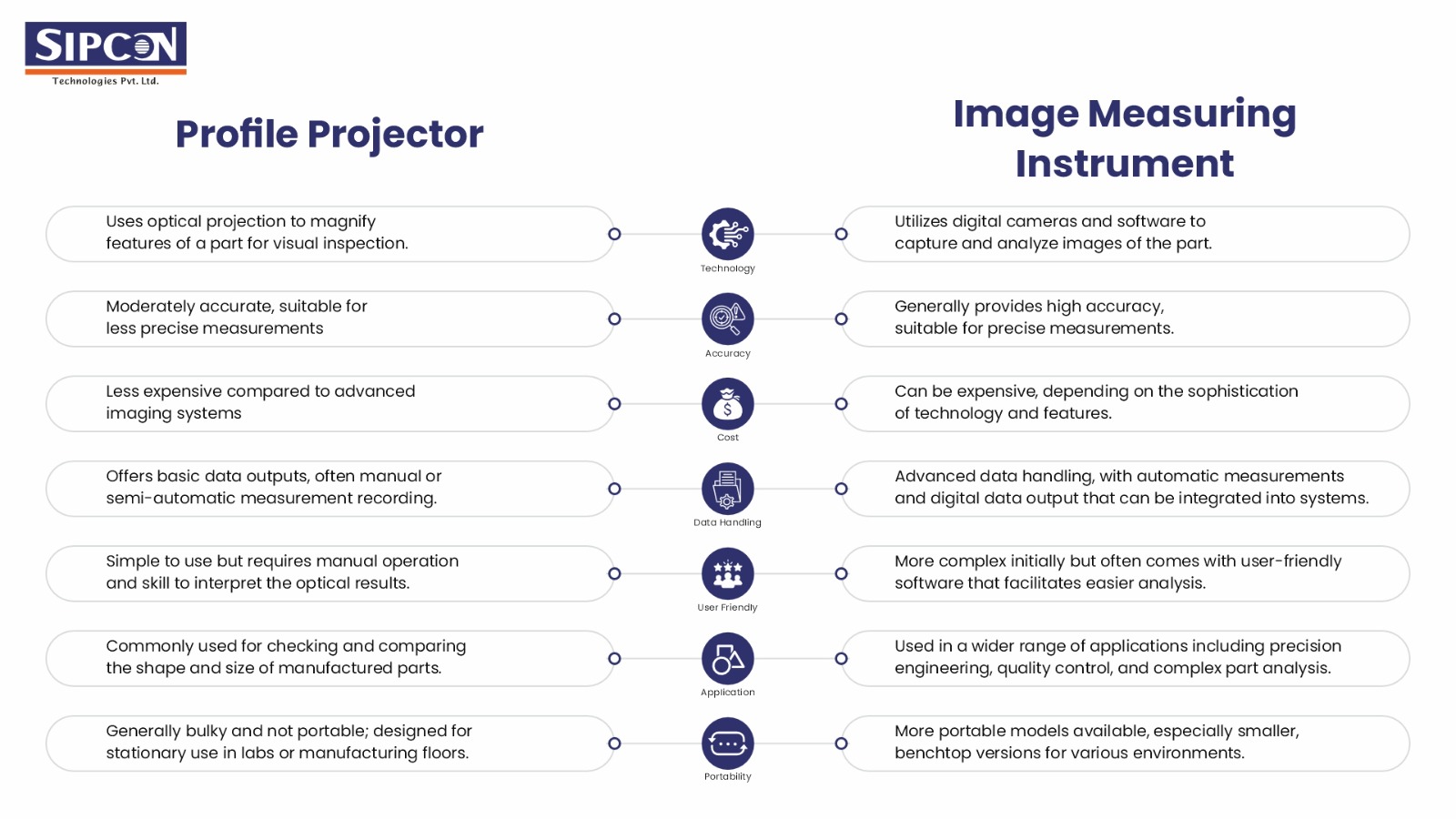

Difference Between Profile Projector and Image Measuring Instrument

Technology

- Profile projector: based on optical technology with a light source projecting the profile of the component onto a screen of the profile projector so the measurement can be done easily.

- Image Measuring Instruments: Image-based measuring instruments use digital cameras and software to capture and analyze the profile for dimensional measurement analysis.

Accuracy:

- Profile Projector: Generally, offers a moderate level of accuracy for the basic measurement equipment and quality control. This measurement equipment is not capable of providing high precision in measurement results of complex parts.

- Image Measuring Instruments: provide high accuracy and precision due to advanced image capturing technology and software, which reduce manual work and also reduce chances of rejection.

User Friendly:

- Profile projector: Demands more manual work for measurements such as the user having to align and focus the part manually, which consumes a lot of time and leads to inaccuracy due to misalignment.

- Image measuring Instrument: As compared to the profile projector, the image measuring instrument is user friendly and easy to operate for unskilled labor.

Applications:

- Profile Projector: Suitable for measurements of small and simple parts such as small machined parts, tool making, and quality control.

- Image measuring instrument: Best for those parts where high precision is necessary such electronics, micro-components assembly, and complex geometries.

Data Integration:

- Profile projector: The biggest drawback of a profile projector is measurements are done manually or requires additional equipment to digitize.

- Image Measuring Instrument: software automatically records and stores measurement data digitally, facilitating easier data analysis and reporting.

-

Cost:

- Profile Projector: Profile projectors are generally used for 2D dimensional measurement with optical technology that why less expensive than Image measuring instruments.

- Image measuring instruments: More costly than profile projectors due to advanced features such as software integration, digital components, and auto edge detection.

Portability:

- Profile Projectors: require a large space for stable setup otherwise it will affect the working of the profile projector.

- Image Measuring Instrument: more likely to be portable, especially newer models designed for flexibility and ease of movement in various industrial environments.

Conclusion

Both profile projectors and image measuring instruments have unique capabilities for different measurement tasks. When you understand the differences in their technology then it will be easy for you to make the right decision according to your measurement needs. As technology advances, we must be aware of them so that we use them to grow our business.