Importance of Void and Contamination Test of Electrical Cables

Introduction

Electrical cables are critical components of various electrical systems, and their proper functioning is crucial for ensuring a safe and efficient electrical supply. To ensure the quality and reliability of electrical cables, it is essential to perform various tests, including void and contamination tests.

Importance and Microscopy Method

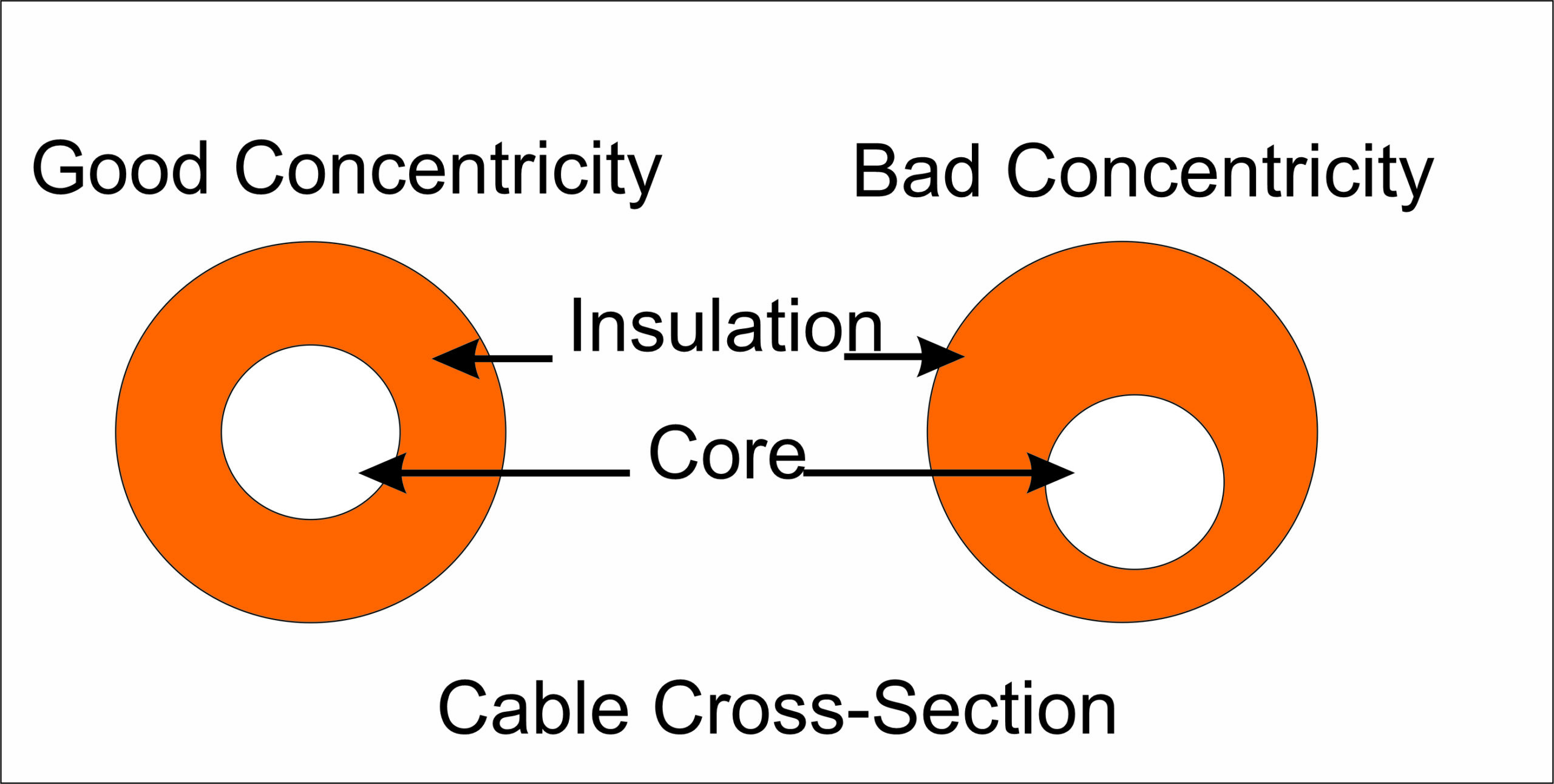

Void and contamination testing of electrical cables are crucial to ensure the absence of any defects that could lead to electrical failure or cause harm to the end-user. A void in a cable refers to an absence of material or empty space within the insulation, while contamination refers to the presence of foreign materials that can reduce the insulation’s quality. These voids and contaminants can cause electrical failure by providing a path for electrical currents to leak out, leading to insulation breakdown and electrical hazards.

The voids present in the cable insulation and the presence of contaminants can cause several problems such as reducing the electrical insulation resistance and increasing the risk of electrical arcing and short-circuits. Void and contamination testing helps identify and measure these voids and contaminants, which are critical factors in determining the cable’s ability to perform its intended function.

Microscopy Method: The Best Option for Void and Contamination Testing

Several methods are used to test electrical cables for voids and contaminants, but the most reliable and accurate method is the microscopy method. This method involves using a microscope to examine the cross-section of the cable and inspect it for any voids or contaminants. This method provides a high-resolution image that precisely identifies any voids or contaminants present in the cable.

The microscopy method is considered the best option for void and contamination testing as it provides a non-destructive, highly accurate, and reliable measurement of the cable’s quality. The method can detect even the most minor voids or contaminants that other testing methods might miss, making it ideal for quality control purposes.

Why Microscopy Method is Best for this Measurement:

The microscopy method is considered the best method for conducting void and contamination testing. This method involves the use of a microscope to examine a cross-section of the cable and measure the voids and contaminants present.

The microscopy method offers several advantages over other testing methods, including:

- High Precision: Microscopy provides high-resolution images of the cable cross-section, allowing for precise measurement of the voids and contaminants.

- Non-Destructive: The microscopy method is non-destructive, meaning the cable is not damaged during the testing process. This makes it ideal for quality control purposes, as the cable can be re-tested later if necessary.

- Repeatable Results: The microscopy method is highly repeatable, providing consistent results every time the test is conducted. This is important for quality control and ensuring that the cable meets industry standards.

Conclusion

In conclusion, the void and contamination test of electrical cables is crucial for ensuring the safety and reliability of electrical systems. The microscopy method is considered the best option for this testing as it provides highly accurate and reliable results that can help identify any potential issues before they become a significant problems. By performing regular void and contamination tests, organizations can ensure that their electrical systems are safe and reliable and that their customers are protected.