Importance of Vision Measuring Systems for Dimensional Measurements

Introduction

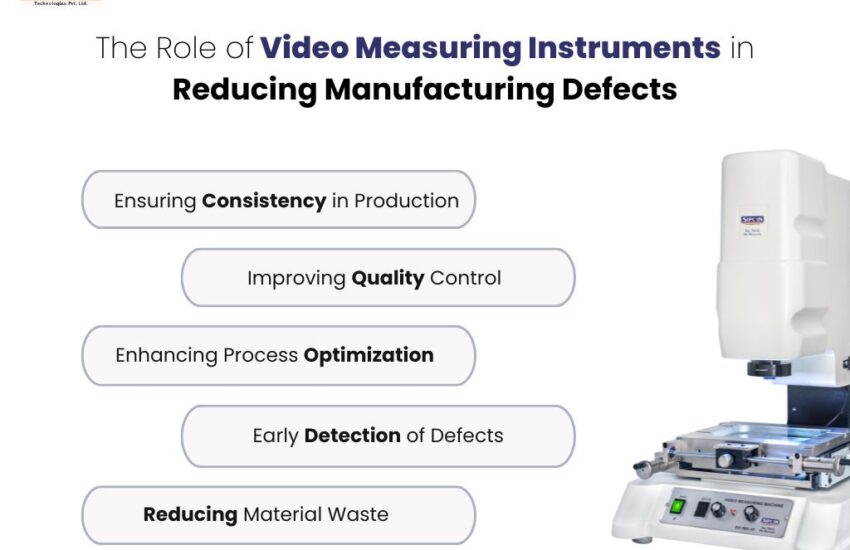

Video Measuring Machines (VMM) or Vision Measuring Systems (VMS) are highly sophisticated inspection tools used to measure and analyze an object’s physical parameters. These systems capture images of an object and use complex algorithms to extract information from those images. In this blog, we will discuss the principle behind these systems and how they are used to improve quality control in manufacturing and industrial processes.

The Principle of Operation

VMM/VMS combines a camera, lighting, and software to create a digital representation of an object. The camera captures an image of the object, and the software analyzes it to determine its size, shape, and other physical parameters. The lighting used in the system is usually bright and consistent, allowing the camera to capture a clear image of the object. The software then uses this image to calculate the desired physical parameters.

The software used in VMM/VMS systems can be divided into two main categories: 2D and 3D software. 2D software is used to analyze the object in a two-dimensional plane, whereas 3D software is used to analyze the object in three dimensions. The 3D software uses the information captured by the camera to build a 3D model of the object, allowing for a more accurate analysis of its physical parameters.

Applications

VMM/VMS systems are used in a wide range of industries for quality control and process improvement. In the manufacturing industry, these systems are used to inspect parts for defects and to ensure that they meet the required specifications. This can include measuring the part’s size, shape, and surface finish, as well as checking for cracks, burrs, or other defects.

In the medical device industry, VMM/VMS systems are used to inspect and measure the dimensions of medical implants and devices, ensuring that they meet the required specifications and that they are safe for use in the human body.

VMM/VMS systems are also used in the aerospace industry to inspect and measure aircraft components, ensuring that they meet the required specifications and are safe for use in flight.

Conclusion

Video Measuring Machines (VMM) or Vision Measuring Systems (VMS) are an essential tool for quality control and process improvement in a wide range of industries. These systems capture images of an object and use complex algorithms to extract information from those images, allowing for the precise measurement and analysis of physical parameters. Whether you are in the manufacturing, medical device, or aerospace industry, a VMM/VMS system can help you improve the quality of your products and processes.