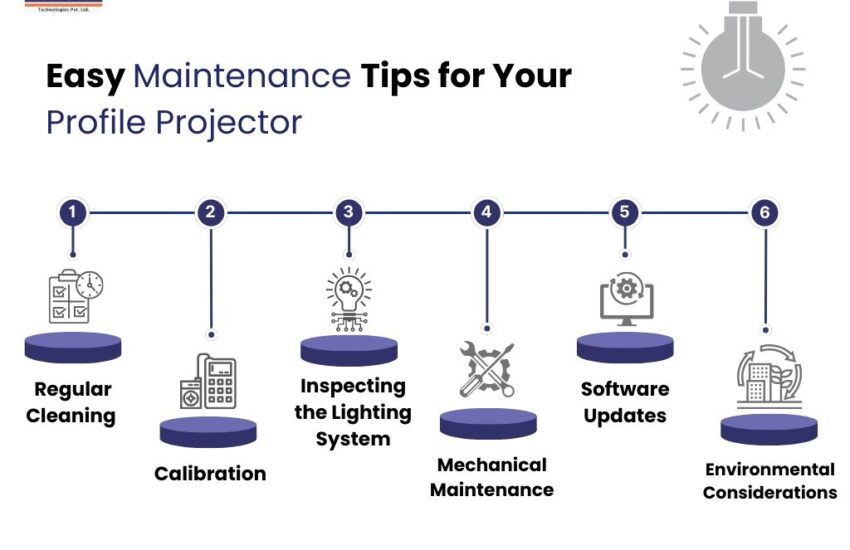

Maintenance Tips for Profile Projector Measurement Machines

Profile projector measurement machines are really important in many industries for making sure things are measured just right and are good quality. Taking good care of these machines is super important to make sure they work well and last a long time. In this guide, we’ll talk about important things to do to keep your measurement machine working its best and lasting a long time.

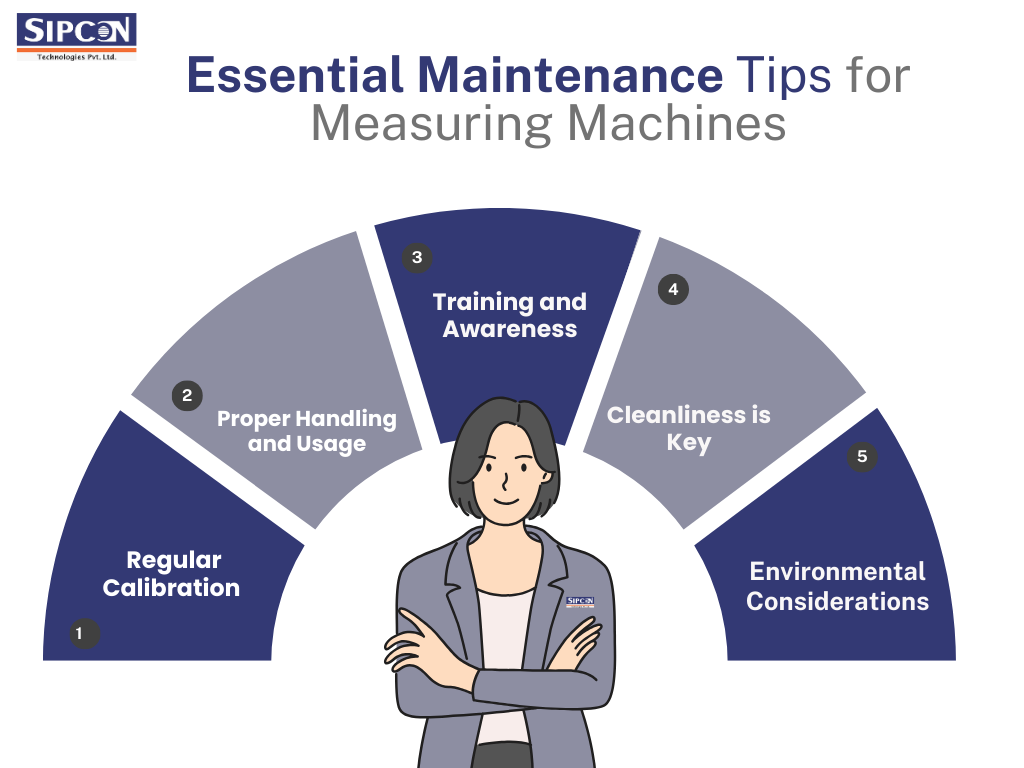

Regular Cleaning and Inspection

One of the fundamental practices in maintaining a profile projector measurement machine is regular cleaning. Dust, debris, or contaminants can impact accuracy. Start by cleaning the lenses, stage, and illumination system with a lint-free cloth and a gentle cleaning solution recommended by the manufacturer.

Perform routine inspections to check for wear and tear on components such as lenses, bulbs, and stages. Any signs of damage or degradation should be addressed promptly to prevent further issues.

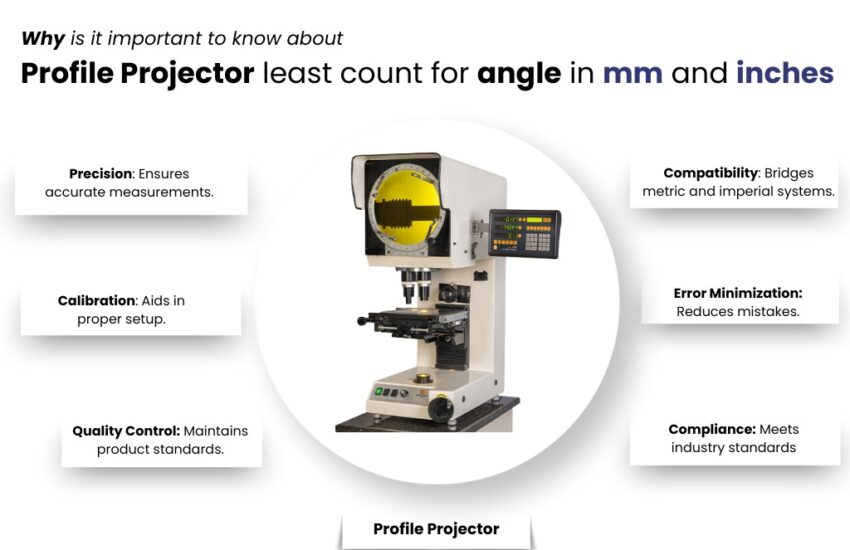

Calibration and Alignment

Calibration and alignment are pivotal for accurate measurements. Schedule regular calibration sessions as per the manufacturer’s guidelines or industry standards. Proper alignment of the optics and stages is crucial for precise results. Ensure that the machine is aligned correctly to guarantee accurate measurements.

Lubrication and Maintenance of Moving Parts

Profile projector measurement machines consist of intricate moving parts that require adequate lubrication for smooth operation. Regularly lubricate moving components as per the manufacturer’s instructions. Over-lubrication can attract dust and impede functionality, so follow recommended intervals and use appropriate lubricants.

Inspect other moving parts such as stages, focus mechanisms, and fixtures for any signs of wear and tear. Replace or repair these parts as necessary to maintain optimal performance.

Software Updates and Upgrades

In today’s digital age, many profile projector measurement machines come equipped with software for enhanced functionality. Stay updated with the latest software releases and upgrades provided by the manufacturer. These updates often include bug fixes, improved features, and enhanced compatibility, contributing to better performance and accuracy.

Proper Storage and Environment

The environment in which the profile projector measurement machine operates significantly impacts its performance. Store the machine in a clean, controlled environment with stable temperature and humidity levels. Protect it from excessive heat, moisture, or vibrations that could affect its precision.

Employee Training and Usage Guidelines

Ensure that personnel operating the profile projector measurement machine are adequately trained. Provide comprehensive guidelines for proper usage, handling, and maintenance procedures. Educated and trained users are less likely to cause accidental damage and can perform routine checks effectively.

Conclusion

Maintaining a profile projector measurement machine involves a series of meticulous steps to guarantee accurate measurements and prolong its lifespan. Regular cleaning, calibration, lubrication, software updates, appropriate storage, and user training are integral parts of a comprehensive maintenance regimen.

By adhering to these maintenance tips, you can optimize the performance of your profile projector measurement machine, ensuring precise measurements crucial for quality control across various industries.

If you have any questions or need more information, feel free to reach out to our technical expert. You can contact us at info@sipconinstrument.com or call us at +91 82229 29966.