Navigating Common Challenges in Profile Projector Measurements: Expert Solutions

The profile projector is a crucial tool for precise measurements in various industries. Despite its importance, it faces common challenges that can affect its performance. In this article, we, as experienced experts, discuss these issues and provide practical solutions for better measurements.

Understanding the Basics

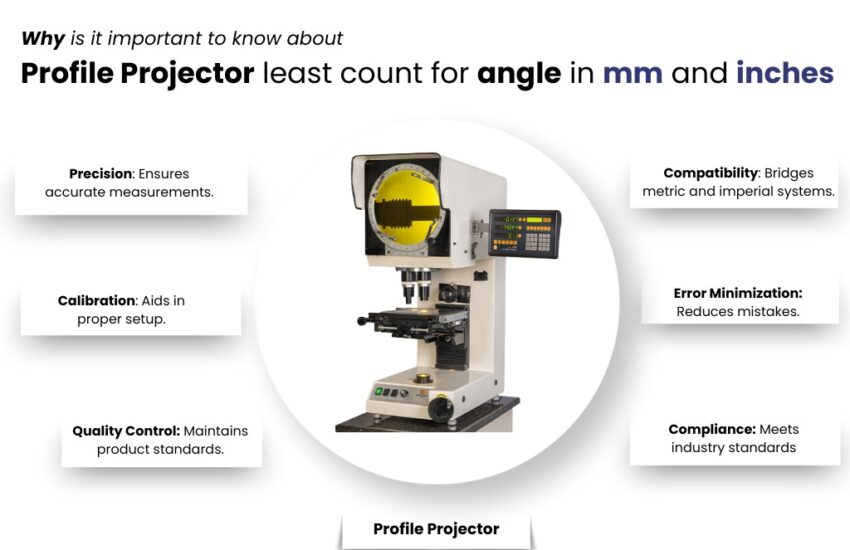

Calibration Challenges

Calibrating profile projectors is crucial for accurate measurements. Even tiny errors in alignment can mess up your results. To fix this, carefully stick to the instructions from the projector maker for calibration. It’s also important to regularly double-check the calibration to catch any issues early on and make sure your measurements are spot on. This helps avoid mistakes that could mess up the accuracy of your data.

Illumination Issues

Good lighting is crucial for a profile projector to work well. If the lighting is not good enough, it can make things hard to see and mess up measurements. To fix this, make sure to check and clean the light source of the projector regularly. Use good-quality bulbs and diffusers to make sure the lighting is always good, helping you get accurate readings.

Overcoming Operational Hurdles

Surface Variation Challenges

when you’re using a profile projector to measure things in the real world, the problem is that objects aren’t always smooth or even. This can mess up your measurements. To fix that issue, use fancy computer programs that come with the projector. These programs can adjust for the bumps and dips on surfaces, making sure your measurements are accurate even on uneven objects.

Data Analysis Dilemmas

Analyzing data from a profile projector might seem difficult, but you can make it easier by using advanced software. These tools can handle complex measurements, making it simpler to understand the data. This way, you can make decisions faster and solve problems more quickly.

Maximizing Efficiency in Measurement

Automation Advantages

Taking measurements manually takes a lot of time and can have mistaken. Use automation to make measuring faster and more efficient. Automated profile projectors with advanced features can cut down on human errors, giving you reliable and consistent results.

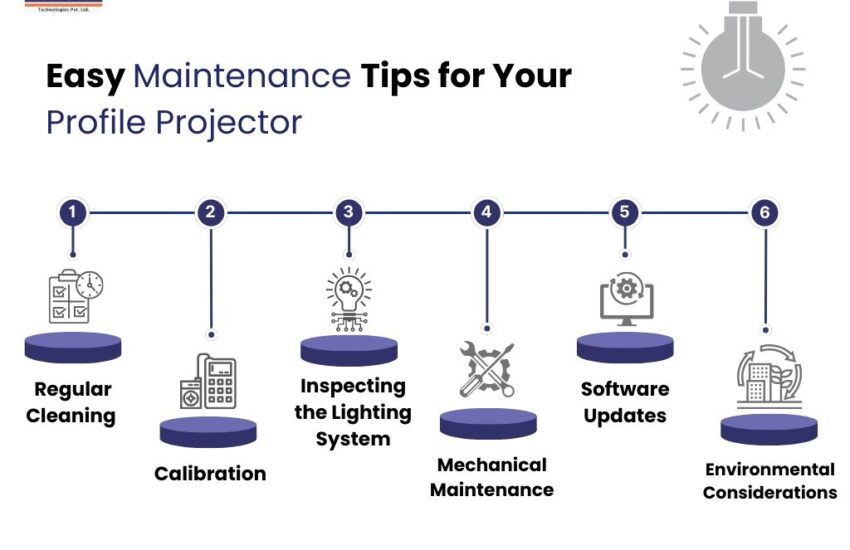

Regular Maintenance Matters

Profile projectors need regular upkeep to work really well. Create a thorough maintenance plan that involves cleaning the lenses, inspecting the moving parts, and making sure the calibration is accurate. Doing these tasks regularly helps prevent issues and makes your profile projector last longer, reducing the time it might be out of commission.

Conclusion

It’s important to handle the difficulties that come with profile projectors and dimensions measuring instruments to get precise and dependable measurements. To do this, make sure the projector is calibrated correctly, use the right lighting, deal with any differences in the surface being measured, and consider using automation. These steps will help make sure the profile projector works well and gives accurate results.