Optimizing CMM Performance: Navigating Environmental Influences

In the world of making things with extreme precision, the performance of coordinate measuring machines stands as a gamer changer for ensuring product quality and consistency. but their effectiveness is directly related to environmental factors. It’s vital to understand how multiple environmental factors like temperature and humidity can affect the performance of CMM.

Importance of CMM Performance

CMM performance is indispensable in different industries, including aerospace, automotive, and medical device manufacturing. Provide accurate measurements and guarantee that the final product matches with exact measurements. It also minimizes costly rework and rejections.

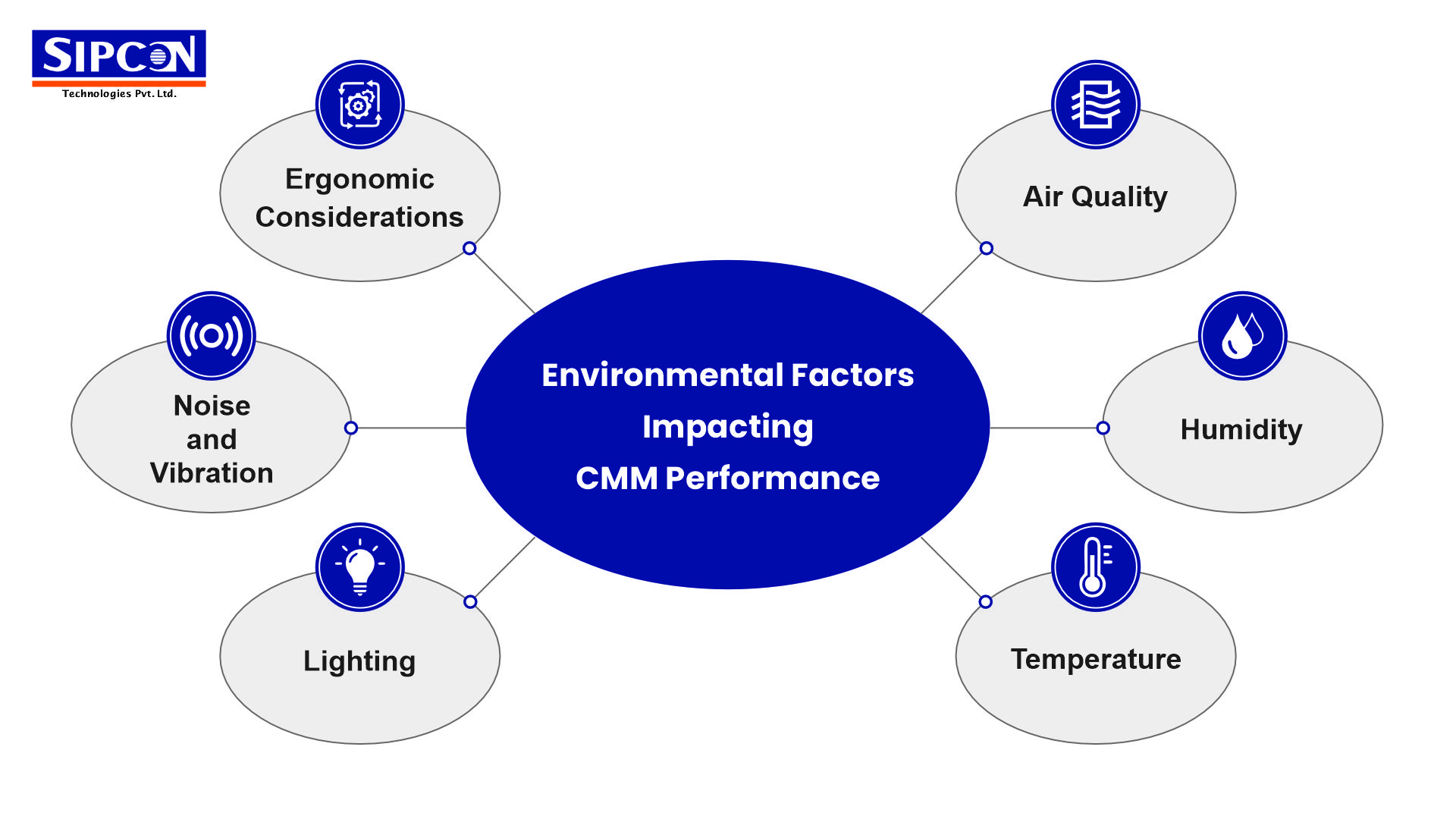

Understanding Environmental Factors

Environmental factors can affect CMM performance. From ambient temperature and humidity levels to air quality, lighting conditions, and even noise and vibration levels, each variable plays a pivotal role in shaping the accuracy and reliability of CMM measurement.

Impact of Temperature on CMM Performance

Temperature fluctuations exert a pronounced effect on CMM accuracy and repeatability. Thermal expansion and contraction of machine components can introduce dimensional variations, leading to measurement inaccuracies. Mitigating these effects requires meticulous temperature control within CMM environments, coupled with thermal compensation techniques.

Effects of Humidity on CMM Performance

High humidity levels can affect the performance of CMM and cause condensation on machine parts, risking measurement accuracy and the machine’s lifespan. That’s why maintaining the right temperature is crucial.

Influence of Air Quality on CMM Performance

Air quality directly affects CMM accuracy. Such as dust, can interfere with delicate measurement processes. Maintaining the right air quality through filtration is crucial to safeguarding the CMM performance and minimizing measurement errors.

Role of Lighting in CMM Performance

Proper Illumination plays an important role at the time of measurement process so that the object can visualized for inspection. Appropriate lighting can minimize shadows that could lead to measurement errors.

Noise and Vibration Effects on CMM Performance

Excessive noise and vibrations can disrupt the measurement process. Vibrations can cause measurements to fluctuate, leading to unreliable data. It is crucial to minimize exposure from external noise and vibrations for better results from CMM.

Ergonomic Considerations for CMM Performance

Ergonomics play a pivotal role in enhancing operator comfort and efficiency during CMM utilization. Optimizing workstation layouts, incorporating ergonomic fixtures, and prioritizing user-friendly interfaces contribute to a conducive working environment and bolster overall productivity.

Conclusion

Understanding and managing environmental factors is crucial to minimizing the CMM performance and lifespan, especially for dimensions measuring instruments. It is important to consider various environmental factors such as lighting, humidity, temperature, noise, air quality, and vibrations which will help you to enhance your metrology accuracy, streamline operations, and uplift product quality standards.

FAQs

What are the primary environmental factors influencing CMM performance?

Proper temperature, humidity, air quality, noise, and lighting all play vital roles in CMM performance and allow to provide reliable results,

How can temperature fluctuations affect CMM measurements?

Any change in temperature, humidity and other environmental factors can affect the performance of CMM, and lead to measurement inaccuracies.

Why is humidity control essential for maintaining CMM performance?

High humidity can cause condensation on machine parts, damaging the machine and affecting measurement accuracy.

What role does lighting play in CMM inspections?

Appropriate lighting is important to ensure clear visibility of workpieces and measurement features during inspections.

How do noise and vibration levels impact CMM operations?

Excessive noise and vibration levels can disrupt CMM operations, leading to erratic measurements and diminished precision.