Profile Projector Least Count for Angle in mm and Inches

Introduction

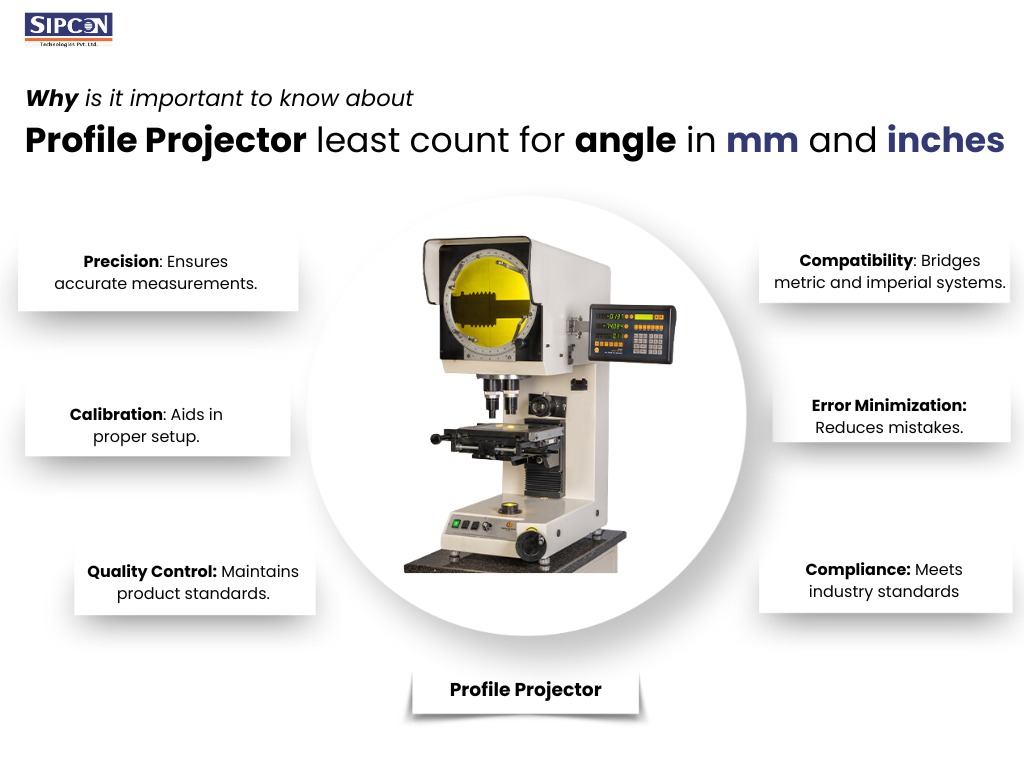

Suppose I say that there is something that is used by the top manufacturers that helps them achieve precise measurements in their products. The secret tool that they use is a profile projector; the key core of its precision is the least count.

With the help of this blog, you’ll explore what least count is, specifically for angle measurements, and how it is shown in both millimeters (mm) and inches.

What is a Profile Projector?

A profile projector, also called an optical comparator, is a device that magnifies the profile of a part on a screen. This will allow you to measure and inspect the dimensions and angles of various parts. We can say that profile projectors are crucial for better manufacturing and quality control.

Understanding Least Count

The least count of an instrument is the very least measurement that can be accurately read. For profile projectors, this decides at what level the precision can go in angle measurements. The smaller the least count, the greater the accuracy.

Least Count for Angles

When we go for angle measurement, the least count is the smallest angular increment that can be measured. Angle measurement is very crucial for industries where the minimal deviation can affect the whole process; planning and quality control that you have decided before, and thought bingo this will politely drag my business into the profit pool.

Least Count in Inches

The least count in inches is also very important to function the manufacturing properly. A common least count might be 0.001 inches, allowing for really very precise measurements. A Few examples where this is particularly useful in industries like- Aerospace and automotive, where precision is paramount and mistakes are the words that can’t be afforded by any one of the industries.

Comparison: Millimeters vs. Inches

Benefits of Using mm

- Millimeter is the part of the metric system, which is adopted universally. This can align with international standards and this allows communication and collaboration with different countries and industries.

- Millimeters are easily convertible within the metric system, it simplifies the calculations and conversions between different units of length- like centimeters and meters. This makes the conversion easier and streamlines measurement processes and minimizes errors.

- Various computer-aided-design (CAD) software packages set millimeters as the default unit of measurement. Use of millimeters on the profile projector, the measurements can be directly input into CAD software and make your process one step shorter, while enhancing workflow efficiency

Benefits of Using Inches

- In a few industries, particularly in regions like the United States, inches are used as traditions for measurement. Maintaining compatibility with existing standards and practices can be advantageous for continuous and familiar working.

- For certain preferences, displaying measurements in inches may offer clarity or convenience. Profile projectors with the option to switch between units while measurement gives flexibility to meet different user needs, you are one of those users.

When to Use Each Unit

The units are used as per the requirements of various industries and according to the specific task. In the case of extremely precise measurements, millimeters are often preferred, in the case of inches it’s used in the case for larger scale applications.

Applications of Least Count in Profile Projectors

The least count in profile projector is essential for a wide range of applications in manufacturing, quality control, and engineering, where precise measurement and inspection of parts are paramount and they ensure components fit together perfectly; for ensuring product quality, reliability, accuracy, and compliance with specifications.

Factors Affecting Least Count Accuracy

Quality of Equipment

It’s up to you to choose the profile projectors, but the quality performance is up to profile projectors, higher quality profile projectors have better precision and lower least counts.

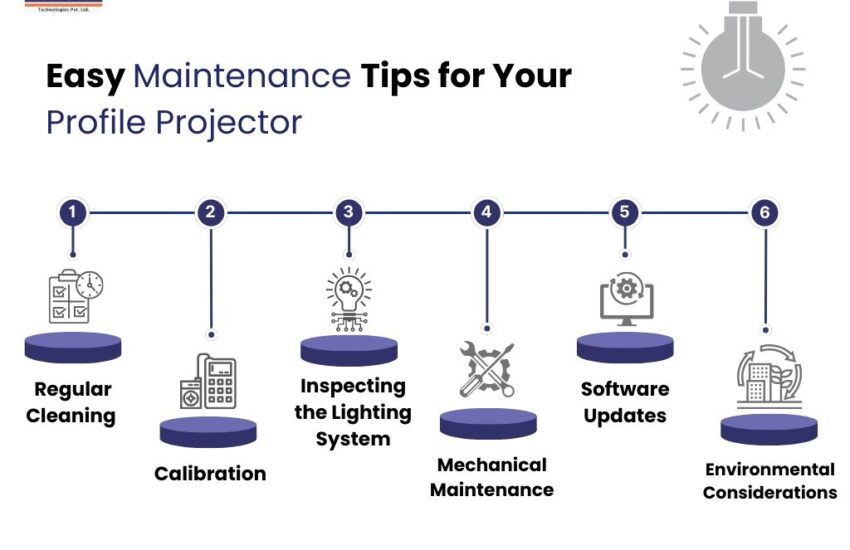

Calibration

As said before profile projector choice is yours just like that choosing the right company is also up to you. Regular calibration is essential to maintain the accuracy. Even the best equipment can give incorrect results if the calibration is not proper.

Improving Measurement Accuracy

Crack the Code: How to Measure like a Boss (Without Losing Your Marbles)

- Regular calibration of your equipment

- To avoid temperature fluctuations use a controlled environment.

Let me stop you from making mistakes

- Never ignore the calibration schedules

- Never use equipment in poor condition

Conclusion

After reading all the details of this blog, now get to know like why it is important to understand the least count of a profile projector, especially for angle measurements, which is crucial in achieving precision. It matters if you’re using millimeters or inches, knowing how to measure accurately can make you close the deviations in the quality of your work.