Seaming Roll & Chuck Inspection and Measurements

Seaming rolls along with chucks are used to hermetically seal the can and maintain pressurization. There are two variants of the seaming rolls: the first operation and the second operation variant which rotates around the can create a seam and then press it completely to close the seam. The shape and conformation of the finished double seam are determined by the contour of the seaming rolls and the taper of the chuck. Therefore it becomes important to have both the seaming roll and chuck in shape at all times.

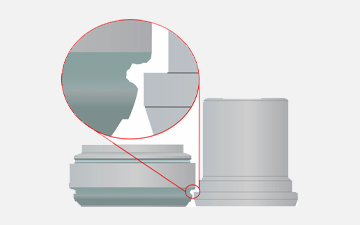

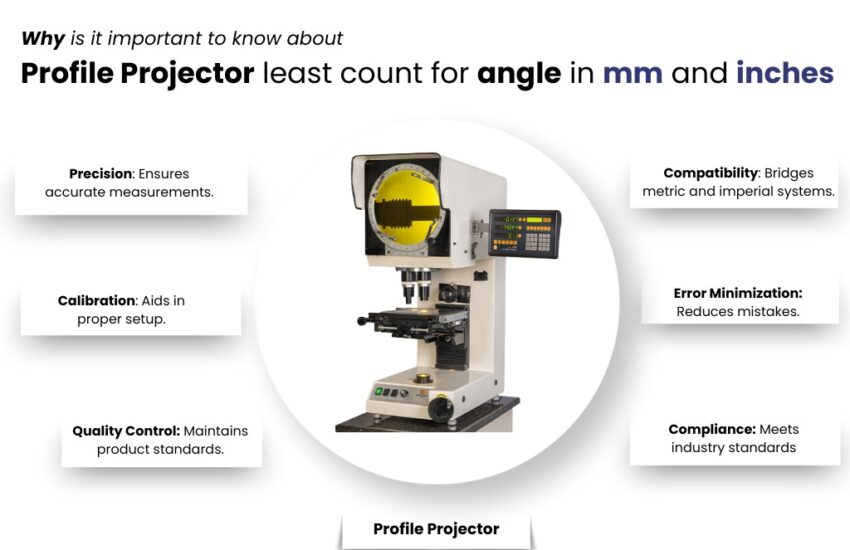

Seaming roll and chuck Inspection and Measurements are a routine operation as they can wear off after some time and need to be inspected at regular intervals. Profile Projectors or Optical Comparators are the most accurate way to detect roll problems. The operator takes out the rollout of the seamer and places it on the work stage of a horizontal profile projector. The contour of the roll is magnified and displayed on the screen so that an operator can readily see the deformities if any. Moreover, using metrology software the contour is compared to a CAD file, and the wears and compared and measured. Deviations from nominal are detected and out-of-tolerance areas are identified. At the end of the inspection, it is clear if the seaming roll is fit for continued use or needs a replacement.