Selecting the Right Field of View Measurement Systems

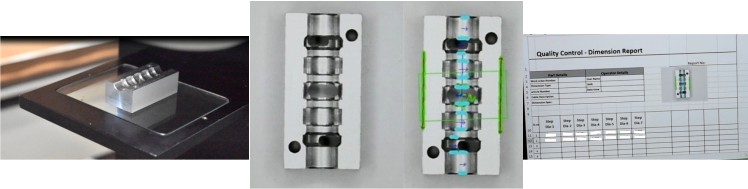

Field of View Measurement Systems are very useful in quality assurance processes as they can instantly measure 2D dimensions of small parts, providing the user the important information about the parts conformance to the standards. They are amazingly quick, measuring more than 100 dimensions in a second and the pass/fail results are simultaneously displayed on the computer screen.

Below are the six important things to keep in mind when selecting the right field of view measurement systems for your quality assurance.

Total Measurement Time

The most important aspect of FOV measurement systems is the total time it takes for the measurement. This time includes placing the part on the glass platform, giving the command for measuring the part to seeing the pass/fail or measurement results. Check to see this total time for one part and calculate the time it will take to measure a complete batch of parts that you plan to measure. Features like auto-alignment, where in the orientation of the part does not affect measurements, Foot switch which frees-up the hand or a touch screen, can significantly cut down the total measurement time.

Accuracy and Repeatability

Apart from the time, the other important aspect is the accuracy and the repeatability of measurement results. Check the specifications to see the systems values. Usually for small FOV systems, less than 60 mm dia, these values are +/- 3microns and +/- 2 microns and as the FOV increases these values go upto +/- 5 microns and +/- 3 microns respectively. FOV systems use sub-pixel image processing that has the ability to measure 1/100th or less of the light receiving element enabling them to use thousands of points for measurements giving accurate results.

Traceability

Check to see that the FOV system is traceable to an international recognised standard.

Results Format

One might need measurement results in an excel format, on the image, color coded tolerances for different features, DXF overlay with profile deviation analysis or a trend monitoring report and statistical evaluation of measured quantities. Make a list of report formats that you will be needing and check the same with the manufacturer.

Easy Programming

FOV measuring systems need a computer program which tells the system the features it needs to measure, the permissible tolerance values etc. Each part profile has a unique corresponding program that does the measurements. Check to see if your parts are covered in the standard library provided by the manufacturer. If the programs are not present, can one on his own create new programs. An ideal Field of View Measurement System will be easy to program for measurements of any type of part.