Things to Consider Before Purchasing an Optical Comparator

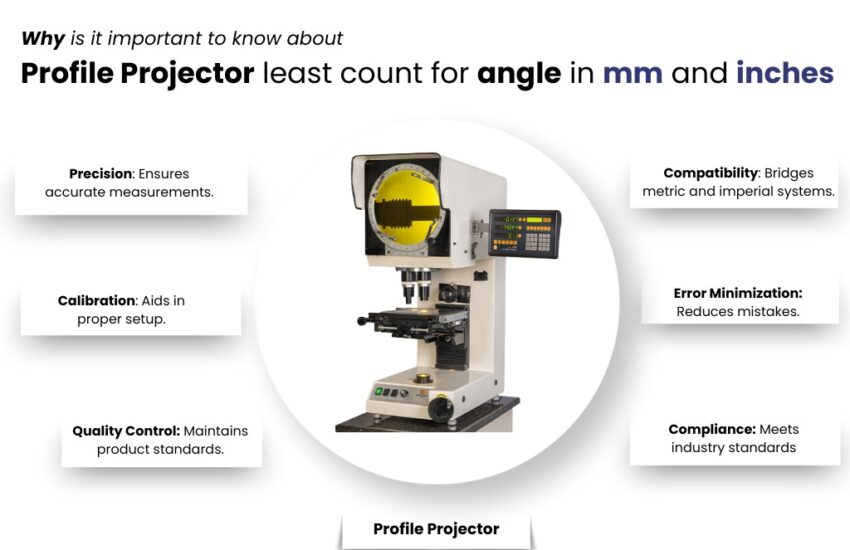

Optical Comparators generally known as profile projectors, are the most commonly tool used in the metrology industry and offer detailed inspection and measurement of components so that each manufactured product meets a specific standard. This blog will work as a guide to you to what critical aspects need to be considered before making a purchase.

Importance of Optical Comparators

Optical comparators can provide high accuracy in the 2D dimensional measurement of parts. They are specially used in quality control processes and detecting manufacturing errors before the running production cycle because a little difference in part can lead to huge costs due to inaccuracy in measurement.

Key Specifications

Magnification Level

Optical comparators offer different magnification levels according to component measurement requirements. It is important to select an optical comparator that can be used to easily magnify the components for examination.

Illumination and Optics

The quality of lighting and optics plays a significant role in the accuracy of measurements. The right optics and flexible lighting options ensure better visibility and precision at the time of inspection.

Advance Software

Modern optical comparators come equipped with software that offers multiple advanced features and reduces manual work such as automatic data capture and analysis, which improves productivity of workflow.

Types of Models

| Type | Description |

|---|---|

| Benchtop Models | Suitable for small parts, compact and fit easily in limited spaces. Perfect for labs or small workshops. |

| Floor Models | Best option for big and heavy parts, suitable for measuring larger components in industrial environments. |

| Portable Models | Provide flexibility and convenience, allowing measurements to be taken directly on the shop floor. |

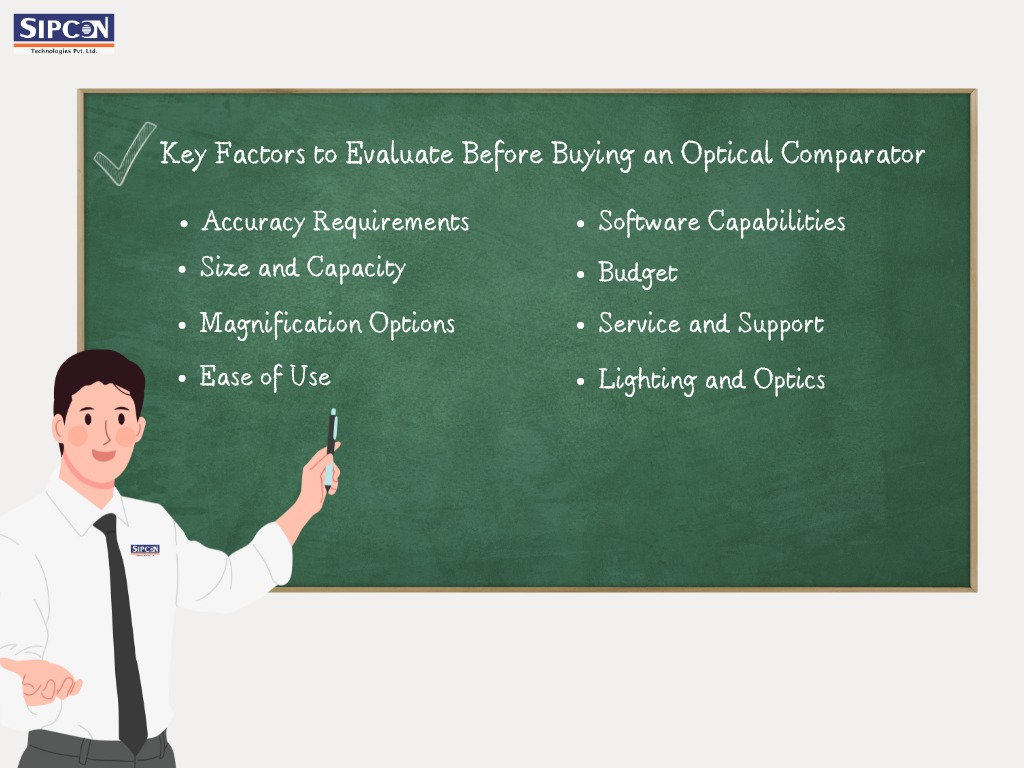

Considerations

Level of Accuracy

First, identify the level of precision needed for your measurement applications. Higher accuracy models are expensive, so select the right model which meets your specified tolerance level.

Ability to Move

Before buying optical comparators consider available workplaces. If mobility is required, consider lighter, portable options.

Budget

The Price of optical comparators varies from features and models. Set a budget under which your requirements can fulfilled compromising on essential features.

Comparison

Always make a comparison of different brands and models to buy the best-fit optical comparator, that meets your measurement requirements at the best cost.

Size and Capacity

Select a model that can handle the size and weight of your component at the time inspection.

Additional Features

Digital Readouts

Digital readouts simplify the measurement process and reduce the data handling manually which reduces human error.

Data Handling

Check for the data handling like USB ports and wireless data transfer to easily integrate the optical comparator with your existing systems.

Purchasing Tips

Where to Buy

Make a list of reputable dealers or direct manufacturers to ensure authenticity and reliable customer service. Take a physical and online demo so that you can understand the essential functionalities of the machine.

Support Service

Consider a warranty and technical support before taking the final decision of purchase, protecting your investment from potential issues.

Conclusion

An optical comparator plays a vital role in improving the accuracy and efficiency of the entire manufacturing process. By considering the above points such as accuracy requirements, size capacity, magnification option, software capabilities, lighting and optics and budget. you will be able to choose the right model of optical comparator that best fits your measurement needs.