Understanding the Applications of Profile Projectors in Industries

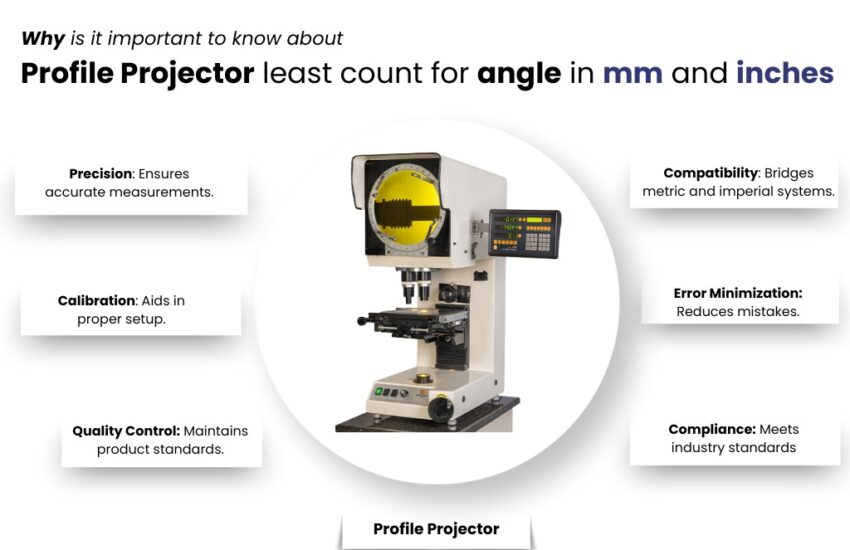

A Profile Projector, also called an Optical Comparator or a Shadowgraph Projector is a specialized measuring system that is broadly classified under the category of Industrial Metrology Systems. It is a versatile and indispensable measuring system in the manufacturing sector where small parts of two-dimensional measurements are required in the R&D, Production, or Quality control departments.

Key Applications of Profile Projectors in Industries

Quality Control and Inspection

In those industries where accuracy in manufacturing is crucial, such as electronics, aerospace and automotive, profile projectors are essential tools for quality control. They are used to inspect the dimensions of intricate parts to ensure that each manufactured part meets standard specifications.

Tool and Die Making

Profile projects are crucial in the tool and die industry, where precise machining and assembly need accurate measurements. Help in checking dimensions of molds and dies, ensure that the final products are made accurately as per standard. Precision in manufacturing is important because of mass production so a minor error can lead to substantial loss.

Measurement and Metrology

The field of metrology- the science of measurement–mainly based on the accuracy of measurement instruments. Profile projectors are reliable tools for measuring angles, diameters, and radii of objects and provide high accuracy.

Reverse Engineering

Profile projectors are also utilized in reverse engineering with reproducing or improving the existing product. Various profiles of parts are projected on the screen of profile projector, so that engineers can inspect the critical dimension without disassembling the entire system.

Research and Development

During the phase of research and development for the product design, profile projector helps engineers and designers visualize changes in existing designs and ensure the product meets all specified standards. This tool is important for reducing the time and cost associated with launching a new product on the market.

Manufacturing Assembly

In the electronics and precision engineering sectors, profile projectors are commonly used to ensure that parts are correctly meeting the standards during the assembly process. This tool plays an important role in industries like semiconductor manufacturing, where high precision is required for placement of parts which is important to device functionality.

Educational and Training purposes

Profile projectors are also required in educational institutions like engineering and manufacturing courses to educate students about metrology and allow students to understand industrial measurement in practical scenarios.

The Benefits of Using Profile Projectors

Using profile projectors in industries offers several benefits:

- Enhanced Accuracy: Offer high accuracy in measurements, which is important for manufacturing and quality control.

- Efficiency: Improves inspection process, especially for complex components.

- Cost-Effective: Ensure no defects in measurements before the manufacturing process which saves costs related to rejection and rework.

- User-Friendly: Advanced profile projector equipped with digital interfaces which is easy to operate for workers.

Conclusion

Profile projectors and dimensions measuring instruments are well-known measurement took in the industrial sector, helping in quality control, manufacturing, and design. This tool can provide high accuracy in measurements which ensure that products are manufactured according to the standards, thus fulfilling industry requirements and consumer expectations. As the industrial sector continues to advance, the profile projectors also undoubtedly grow to meet technological advancements.