What is a Coordinate Measuring Machine? CMM Types, Uses and Applications

In the world of metrology, precision plays a substantial role in meeting the demands of multiple manufacturing and engineering industries. A coordinate measuring machine is mainly used for measuring large and bulky parts. This machine is important for measuring the physical geometrical characteristics of an object.

What is a Coordinate Measuring Machine (CMM)?

A coordinate measuring machine is a measurement instrument that is used in manufacturing and assembly processes to ensure that every component is manufactured as per the standard measurement. CMMS operates using a probe that touches the surface of the object to record precise measurements.

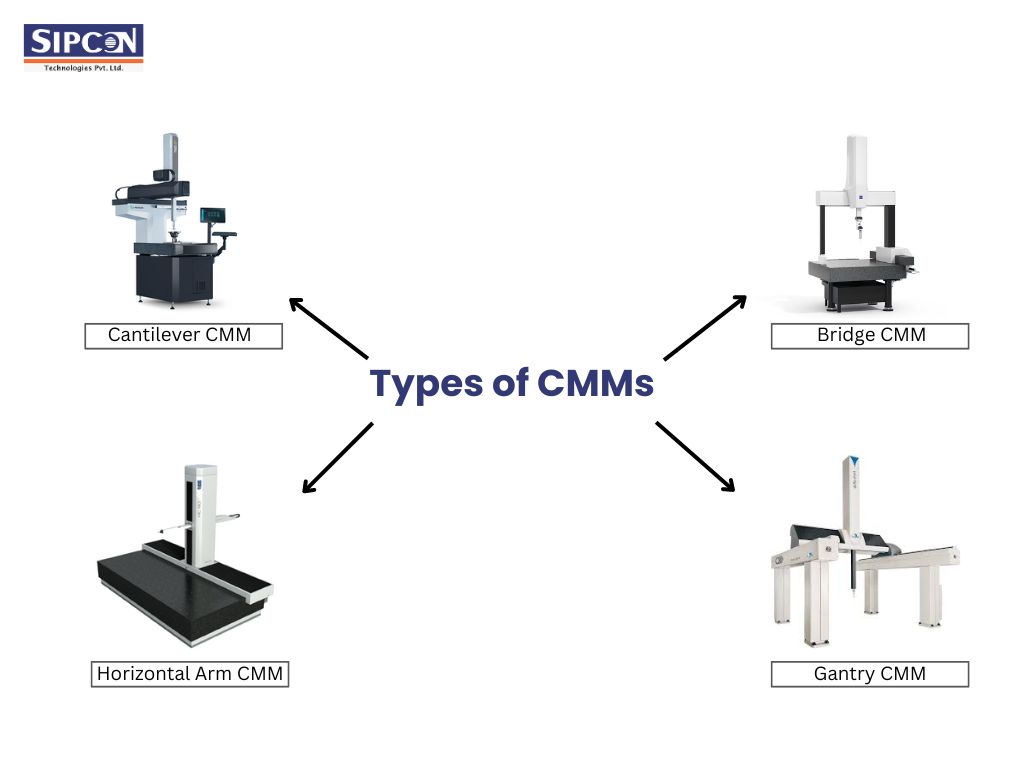

Types of CMMs

There are four main types of CMMs, each suited for different applications and environments:

- Bridge CMM

- Cantilever CMM

- Horizontal Arm CMM

- Gantry CMM

Bridge CMM

Brief Description:

This is the most common type of CMM which is used for measurements. It has a bridge supported by two vertical columns. The measuring probe moves along the X, Y, and Z axes.

Applications:

In the context of versatility, bridge CMM is mostly used for measurements. It is suitable for medium to large size components like automotive and aerospace industries.

Pros:

- More accurate and Precise results

- Ideal for complex geometries

- Sturdy and stable

Cons:

- Acquire Large floor space.

- Costly as compared to other models.

Cantilever CMM

Brief Description:

The cantilever CMM comes with a single support column, along with a flexible measuring arm. This is designed to allow the user to measure the component easily.

Applications:

Cantilever CMMs are ideal for measuring small to medium components such as electronics and small precision engineering parts.

Pros:

- Acquire less floorspace than bridge CMM.

- Ideal for small to medium parts

Cons:

- Not as stable as bridge CMMs

- Not suitable for larger parts

Horizontal Arm CMM

Brief Description:

There is an extended horizontal arm in horizontal CMM which moves with the X and Y axes, with the help of a vertical probe. This measuring machine is suitable for large, flat, and long parts.

Applications:

Horizontal CMMs are the most suitable measuring machines for automotive and shipbuilding industries, where huge components are being measured.

Pros:

- Easily capable of measuring large and flat parts.

- Adjustable and versatile

Cons:

- In comparison to Bridge CMMs, Horizontal CMMs cannot offer high accuracy.

- Occupies larger space than other models of CMMs.

Gantry CMM

Brief Description:

Gantry CMM is just like bridge CMM but in the context of occupying space gantry CMMs consume a larger area than bridge CMMs. It is suitable for very huge parts.

Applications:

This type of CMM is much more suitable for industries like aerospace, shipbuilding, and automotive. Where the parts that need to be measured are extremely large.

Pros:

- It is suitable for the measurement of huge parts.

- More accurate and precise.

Cons:

- Required huge a budget.

- Requires large floor space.

How CMMs are Used

CMMs are used in multiple stages of the manufacturing process to ensure the right measurements:

1. Prototyping:

In this step, CMMs are used to check whether the initial design meets all the measurement specifications or not. The right measurements are very important to determine the variations that occurred out of the standard design.

2. Production

In bulk production, CMMs are utilized for quality control to ensure that each part is manufactured as per the standard measurements. It is important to identify any variation in difference before running the production cycle.

3. Assembly

Each part is important to fit properly, that’s why measurement accuracy is crucial. This is where the CMM plays its role to ensure the perfect assembly of parts.

4. Reverse Engineering:

CMMs can measure critical dimensions and create 3D models for reverse engineering with high accuracy. reverse engineering is performed to upgrade or improve the existing product design.

Conclusion

Coordinate measuring machines (CMMs) play a crucial role in ensuring quality control of manufactured parts. Different manufacturers have different needs, after understanding different types of CMMs like Bridges, Cantilever, Horizontal Arm, and Gantry, and learning about their specific applications, it becomes easier for the manufacturers to choose the right machine as per their requirements. Even if that is for small components or huge industrial parts, CMMs offer high precision in measurements to meet the standards of modern manufacturing.