Why Are Profile Projectors Utilized in Factories?

In the vast landscape of industrial manufacturing, many new tools and technologies are present to check the precision and efficiency of manufactured parts. One such tool is the profile projector. But the question is why are profile projectors used in factories? This blog helps you to understand the role of profile projectors in the manufacturing industry and how this helps in attaining accurate measurements for manufacturing the component.

Understanding Profile Projectors

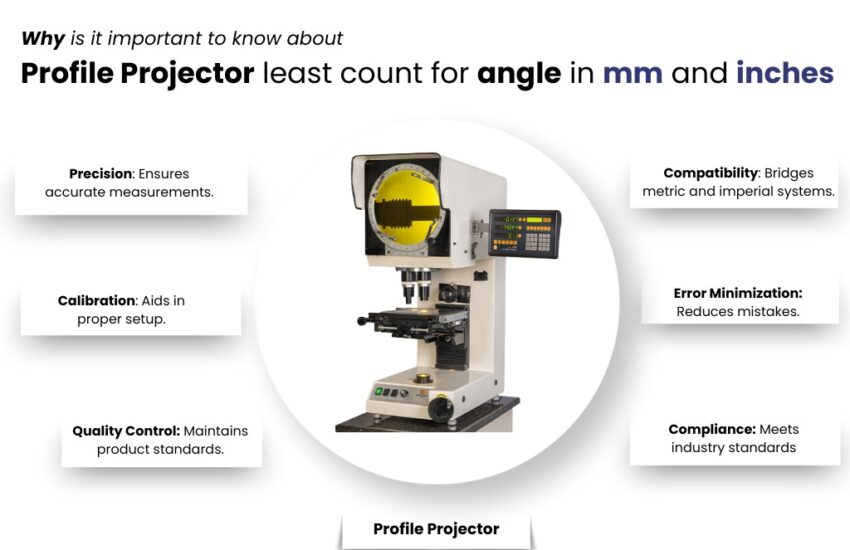

A profile projector, also known as an optical comparator, is an optical measurement device. Which is used to project an enlarged profile of an object onto a screen. Then the projected image is matched with grids and lines on the screen, making it easier to measure and analyze. This technology is specially used in industries where precision and accuracy are crucial, such as automotive, aerospace, and machinery manufacturing.

The Role of Profile Projectors in Factories

In a factory, projectors are commonly used for a variety of measurement tasks for quality control. By projecting the shadow of a component onto a screen which allows manufactures to easily compare it with the standard model. This comparison allows them to recognize any differences or defects, ensuring that the final part is manufactured with the required specifications.

Another vital use of a profile projector is the process of reverse engineering to replicate or improve the component. Profile projector is used to project a detailed image of the component, which is to be analyzed to understand its design and measurements.

Applications in Factories

Dimensional measurements

Profile projectors are commonly used to measure precise dimensional measurements, such as diameters, angles, and radii, which are important in the manufacturing process.

Quality Control

Profile projectors allow inspection of manufacturing defects and ensure that all the manufactured parts meet the industrial standards.

Inspection Processes

Profile projectors streamline inspection processes with a fast and accurate way of measuring the dimensions and shapes of manufactured parts.

Advantages of Using Profile Projectors

The use of profile projectors in manufacturing offers multiple advantages, they provide precision and accuracy in the manufacturing process. With detailed images of an object, manufacturers can easily measure and analyze every detail of the component, thus reducing the chance of errors.

Secondly, profile projectors are multi-tasking tools for measurement. From quality control to reverse engineering, utilized in various stages of the manufacturing process.

Lastly, profile projectors are the most cost-effective tool of all measurement tools which offer accuracy and precision, their long– term benefits in terms of quality control and productivity make profile projectors a great investment for any manufacturing company.

Factors to Consider When Choosing a Profile Projector

Factory Needs

The selection of a profile projector must be based on the specific needs of the factory, such as the types of parts to be measured and analyzed.

Features and Specifications

Essential features and specifications, such as the size of the viewing screen, light source types and magnification capabilities, should also be considered.

Conclusion

In conclusion, profile projectors are an essential tool in the manufacturing industry. This tool ensures precision, accuracy, and quality control in the production process. By projecting the profile of a component onto a screen, manufacturers to easily compare it with the standard design, thus reducing defects and ensuring the production of high-quality products.