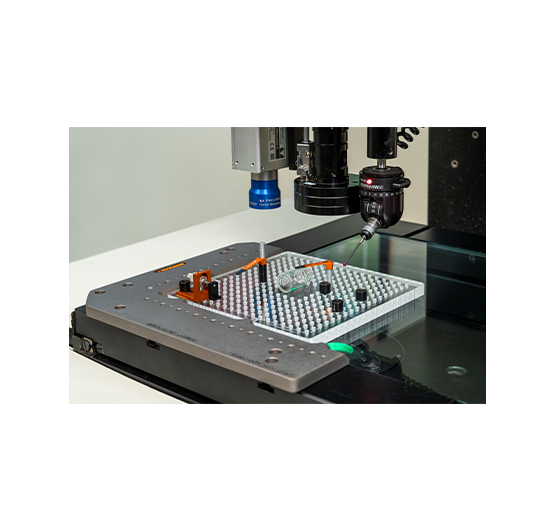

CNC Video Measuring machine or CNC Vision Measurement system provides noncontact dimensional measurements with speed, accuracy, and above all, flexibility. In general, with features that are mainly microscopic, or with flat parts where operators cannot physically touch an edge it is best to use a vision measuring system.

- Magnification range from 9X-500X

- Measuring range from 100x100x100mm to 500x400x300mm

- Full 3D software with least count – 1/0.5/0.1 micron

- Fully integration with CAD for reverse engineering application

- Stable Granite base construction

- Accurate Servo or Stepper motor CNC control system

- Autofocus

- Thread less worktable – Zero Backlash

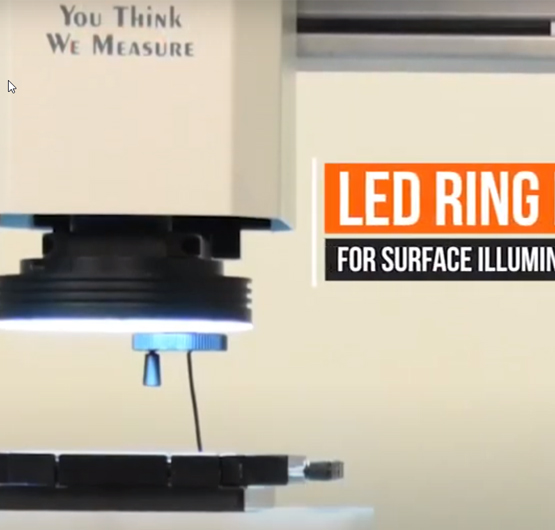

Sipcon Video measuring machines are capable of measuring edges anywhere on the parts using a variety of lighting techniques like quadrant lighting, pad lighting, ring lighting and coaxial lighting. If something can be measured optically and tactilely then vision system will give you the fastest and most accurate results. High speed repetitive inspection even of complex geometric features increases productivity dramatically.

After first piece of inspection, measurement functions and stage movement are driven by the closed loop positioning system, and take place automatically, without operator’s intervention or subjectivity. Affords internal process control, lets you generate Histograms, X-bar, Range and sigma charts, and other pertinent capability and process control data.

To know more about this product —

| Model No. | SVI-5300-CNC-V | SVI-5300-CNC-VT | SVI-5300-CNC-VTL |

|---|---|---|---|

| Software | Ik 5000 / MSU3DPRO | ||

| Measuring Range-Standard | 250 X 150 X 200 mm | ||

| Measuring Range-Optional | X-axis upto 500mm, Y-axis upto 400mm, Z-axis upto 300mm | ||

| Resolution | 0.005/ 0.001/ 0.0005/ 0.0001mm | ||

| Linear Accuracy | (3+L/200) micron | ||

| Repeatability | ±(0.002mm) | ||

| Vision | 1/3" High Resolution CCD Camera | ||

| Magnification | Optical Magnification 0.7X - 4.5X & Magnification on Monitor 35X - 225X | ||

| Video Edge Detection | Standard | ||

| Optional Hardware | PC +19' TFT Monitor | ||

| Illumination Surface | Fibre Optic/LED | ||

| Illumination Contour | Halogen Lamp/LED | ||

| Operation | Manual with Quick Release Knob & CNC | ||

| Base Platform & Column | Granite | ||

| Platform Load Capacity | 30Kg | ||

| Power Supply | 220-240 V ± 5%, 50/60 Hz | ||

| Motion Control through Joystick | Standard | ||

| Programmable Lite Control | Optional | ||

| Non-Linear Error Correction | Optional | ||

| Autofocus | Optional | ||

| Touch Probe | X | Renishaw MCP / MH20i | Renishaw MCP / MH20i |

| Laser Probe | X | X | Conoprobe |

This Product is Ideal For —

Automobile

Cutting Tools

Aerospace

Rubber

Electrical

Fasteners & Gears